Portfolio

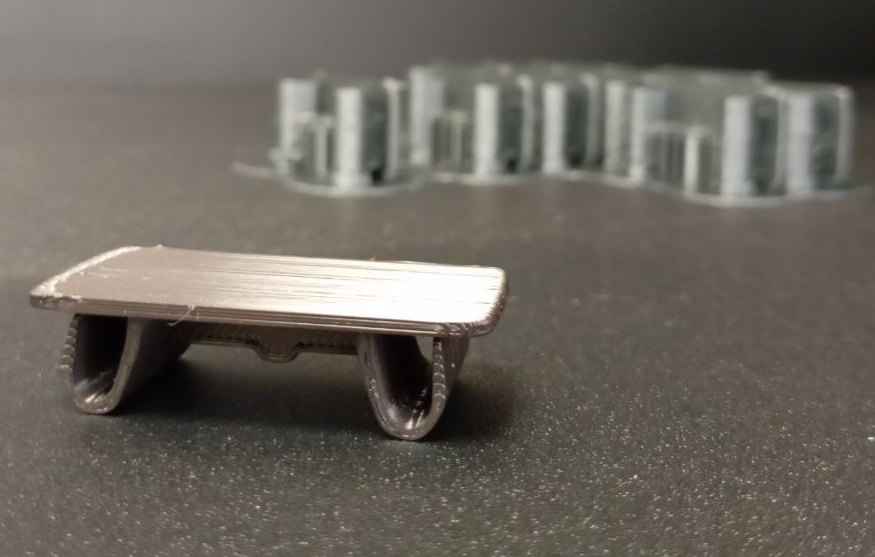

A special order where it was necessary to scan the hood vents, transfer the scanned parts into a 3D format, and design the covers from scratch that would completely cover the hood vents. Special attention was paid to the quality, weight, and functionality when creating these parts. Using 3D printing technology, two covers were made.

After painting and applying special rubber seals, the covers fit snugly to the hood, covering its vents and fulfilling their primary function – protecting the engine from dust and water ingress.

We have designed and manufactured a fairing for a chopper for the client. According to the project, headlights will be installed in the eye holes. For printing, we used PETg (polyethylene terephthalate modified with glycol). This material has minimal shrinkage during printing, allowing for the creation of large objects while maintaining the geometry specified in the model.

An example of serial printing using ABS, where speed was the most important factor rather than high quality. We promptly developed the model and produced 300 covers for the tractor control panel. This project highlights our ability to quickly respond to customer needs and deliver results in the shortest possible time.

Following the wishes of our client, we developed and created a unique model for customizing his motorcycle helmet. This detail, made with an internal cavity and lightweight construction, not only fits the client’s helmet perfectly but was also accurately scanned from it. Thus, we ensured the closest possible match to his requirements and guaranteed the perfect fit of the detail on his helmet. Our team takes pride in the ability to meet the needs of our clients and provide them with high-quality solutions for their individual projects.

Here is a batch of screws specially manufactured for a client who is involved in the development of electric hydrofoils. Carbon-filled plastic was used for their production, which is known for its high strength and resistance to water exposure. This material is ideal for use in marine conditions, providing reliability and durability under high loads and wet conditions.

Project “Car Speaker Mounts”

An order where the main task was to produce high-quality car audio system parts that could be immediately installed and used as intended.

The client sent a prepared 3D file (.stl), which needed to be adjusted and put into production. Using professional 3D printing equipment, two high-quality parts were successfully produced.Project “Car Speaker Mounts”

An order where the main task was to produce high-quality car audio system parts that could be immediately installed and used as intended.

The client sent a prepared 3D file (.stl), which needed to be adjusted and put into production. Using professional 3D printing equipment, two high-quality parts were successfully produced.